Aside from application errors and faulty waterproofing products, there's another factor that people usually forget when waterproofing roof decks, which has now become one of the most common causes of waterproofing failures…

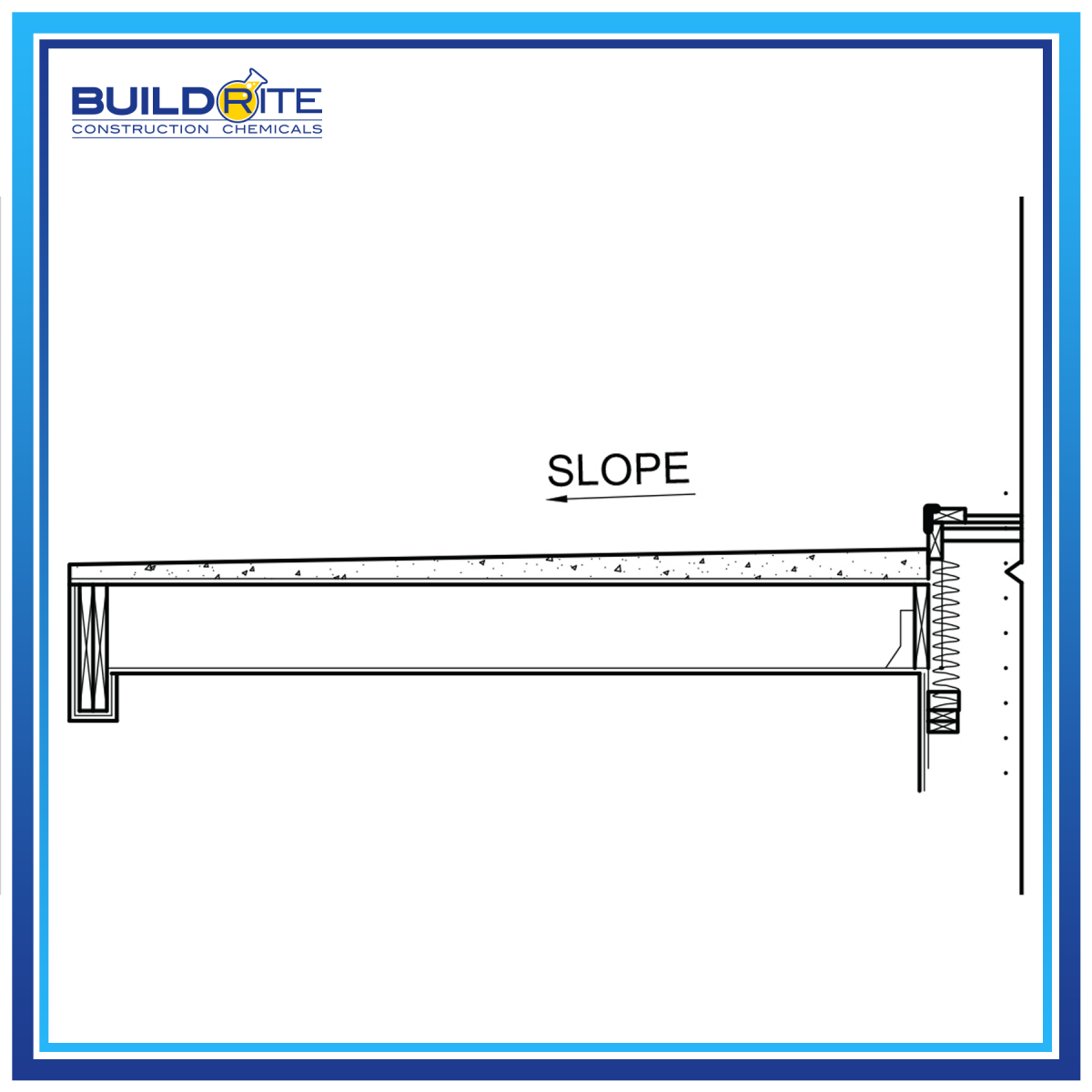

SLOPE TO DRAIN

If you have a roof deck, you probably know the headaches of having ponding problems. These are the puddles of water that accumulate on the roof deck when it rains.

When the roof deck has an effective waterproofing system, water accumulation is not usually considered a problem. However, it becomes problematic when the ponding water slowly damages the system, especially when the ponding water is constantly exposed to sunlight.

As a waterproofing expert at Buildrite, I've already encountered many complaints about ponding problems on roof decks and the failure of their waterproofing system. This is why Buildrite promotes the installation of an effective slope to prevent early deterioration of the waterproofing system on roof decks and bathrooms.

Fortunately, ponding problems can be easily eliminated using a topping that can be applied at a very thin application. But, before installing one, you have to consider several factors first.

- Substrate Condition

Make sure that the substrate is still sound.

Leaks on roof decks and the failure of the waterproofing solution are usually caused by hidden damages on the slab. Cracks, dusting surfaces, or weak concrete surfaces are the major reasons concrete toppings delaminate over time.

Cracks may have formed on the slab due to the corroded reinforcements. Poor mix design and workmanship may also contribute to the early deterioration of the slab.

If your waterproofing system fails, you should check the slab before applying a new system. You have to remove all existing membranes to reveal structural cracks and concrete delamination.

See this video to learn how you can repair structural cracks: https://youtu.be/bpYOViHXJnw

- Load Capacity

Factor in all the load your roof deck will carry, including the furniture, foot traffic, equipment, etc. Applying a topping can drastically increase the structural load, leading to the formation of structural cracks if the roof deck can't support additional loads.

You can ask your engineer about the load capacity of your roof deck. You may also consider consulting a professional contractor to assess your roof deck.

3. Thick-Bed vs. Thin-Bed

If you’re planning to install tiles on top of the waterproofing underlayment, you have to know that there's a better way to do it.

a. The Thick-Bed method is the traditional way of installing tiles. In this method, a dry pack or tile adhesive is applied as a mortar bed over the substrate. It is usually applied with a thickness of 15mm to 25mm, depending on the size of the tiles. Traditional tile setters use a dry pack to correct the floor level and install tiles at the same time. But this is one of the major causes of cracking and debonding.

Due to the thickness of the mortar bed, voids are more likely to form under the tiles. In this method, creating a slope using the thickness of the mortar is really hard.

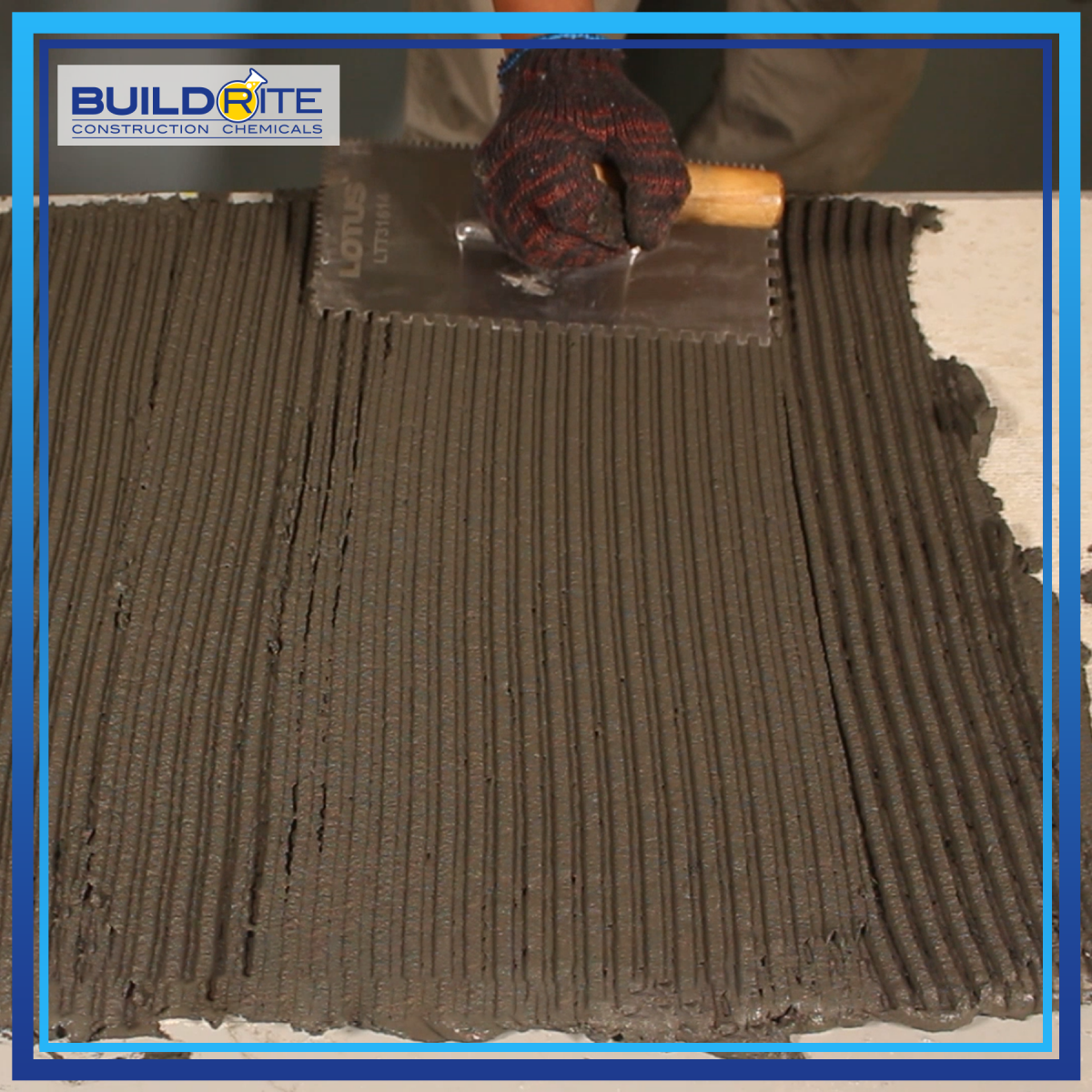

b. The Thin-Bed method is the way of laying tiles with a thin layer of tile adhesive. 3mm, 6mm, or 10mm notched trowels are used, depending on the size of the tile to control the thickness of the tile adhesive.

With this method, the sloped topping should be applied over the underlayment, and the tiles are then applied using the appropriate trowel size. This method is recommended by ANSI (American National Standards Institute) as it prevents the formation of kapak compared to the traditional thick-bed method.

4. Application of Thin Topping

Here at Buildrite, we discourage using an ordinary concrete mix for creating a slope because regular concrete can't achieve the required compressive strength at such thin applications. This is why you may have noticed that ordinary concrete usually delaminates when used on feather edges.

What we can recommend is Buildrite Hardcrete 310. It is a cementitious pre-packed repair mortar specially designed for resurfacing, patching, and repairing large areas of concrete. It can achieve 3500psi after 28 days at a minimum thickness of 10mm. It is recommended for installing slopes as it can achieve the required compressive strength at such thin applications. For roof decks that are exposed to high traffic or load, we recommend using Hardcrete 510 (5000psi at 10mm).

What we can recommend is Buildrite Hardcrete 310. It is a cementitious pre-packed repair mortar specially designed for resurfacing, patching, and repairing large areas of concrete. It can achieve 3500psi after 28 days at a minimum thickness of 10mm. It is recommended for installing slopes as it can achieve the required compressive strength at such thin applications. For roof decks that are exposed to high traffic or load, we recommend using Hardcrete 510 (5000psi at 10mm).

Get Rid of Ponding Forever

Keep the water where it's supposed to be.

Installing a slope is the best way to prolong the lifespan of your roof deck while keeping it easy to maintain. It is, therefore, crucial to install an effective slope to prevent costly repairs and inconveniences in the future.

Once you're done installing a slope on your roof deck, you can watch this video to learn more about roof deck waterproofing: