Have you noticed those small bumps on your floor coating?

Those are called blisters, and they’re a total bummer! Blistering on your floor coating means only one thing: INCONVENIENCE due to additional repair cost, downtime, and required labor.

The formation of blisters is actually fairly common, especially during the rainy season.

Fortunately, it’s really easy to solve this problem once you learn the science behind it.

Blisters or Bubbles?

First, you have to know the difference.

Those bumpy portions on your floor coating could either be blisters or bubbles.

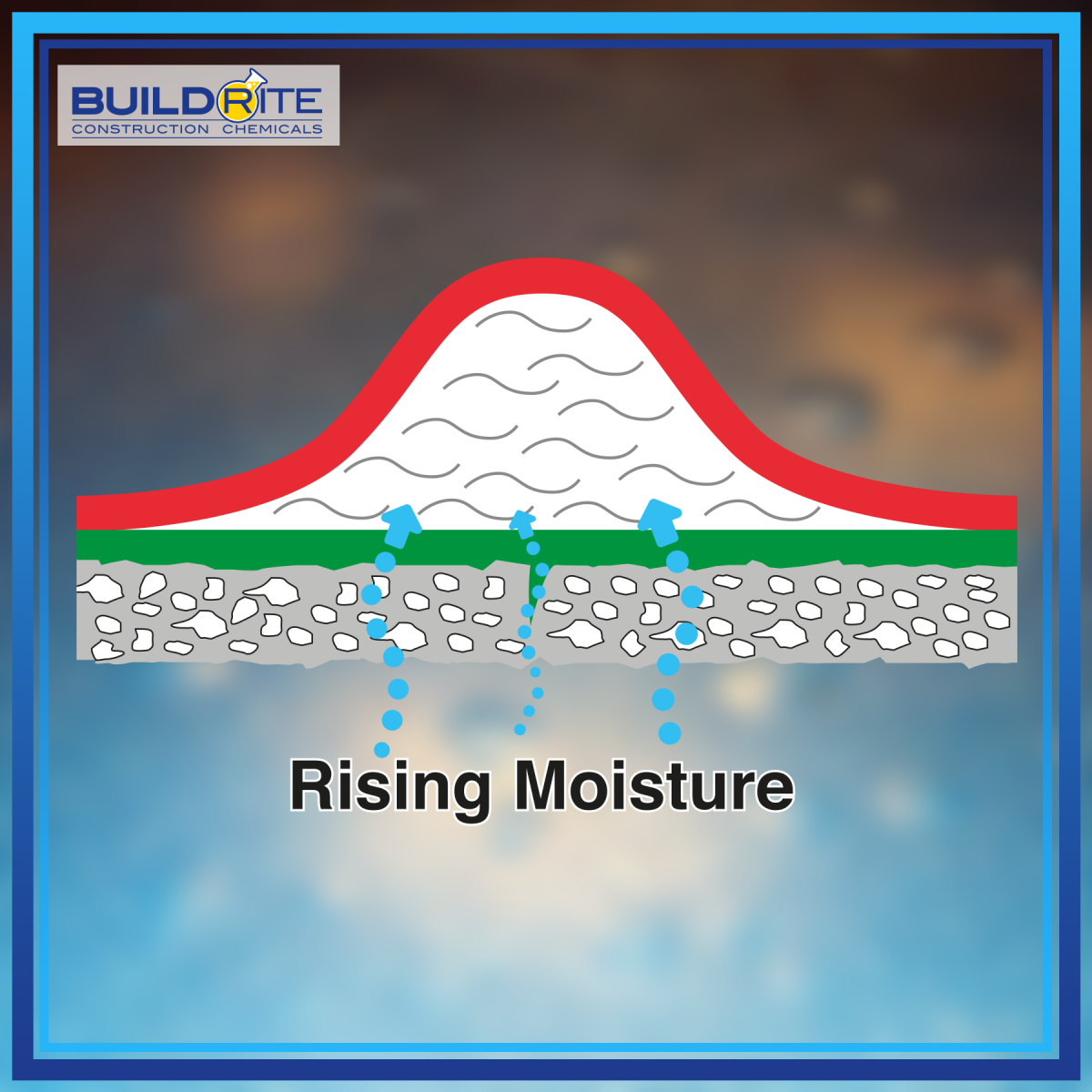

1. Blistering – This floor coating problem is caused by osmotic pressure – or the moisture (vapor) pushing the coating upwards. It usually happens in cold places or areas with high humidity. The moisture could either be from below the ground or from the concrete itself.

Due to its porosity, concrete also has a tendency to absorb moisture, which can later cause blisters. If the room has high humidity and the floor is cold, moisture (condensation) could appear on the concrete floor. This will result in poor adhesion and eventual blistering of the floor coating.

2. Bubbles – Temperature is the main cause of this floor coating problem, particularly during the curing process. Due to uneven temperature, the top layer of the floor coating dries faster than the lower portion, leading to the formation of bubbles. The porosity of the substrate and the thickness of floor coating could also cause uneven curing and formation of bubbles.

Wrong Methods That Lead to Blistering

At the end of the day, blisters on floor coating appear because the wrong methodology and system were used.

1. Traditionally, prior to the application of floor primer, they measure the moisture content of the substrate and relative humidity using an Infrared Thermometer and a Thermo-Hygrometer. As a rule of thumb, the ideal moisture content of the substrate is less than or equal to 4%.

Ordinary Primers only promote good adhesion but don’t prevent osmotic blistering. Without the ability to block moisture, applicators have to measure and make sure that the substrate and humidity meet the right condition before applying the floor coating system.

2. “Self-priming” floor coatings have also become a trend in the industrial flooring industry. However, considering the chemistry of concrete and floor coatings (and based on our experience), self-priming floor coatings don't solve blistering.

While it promotes good adhesion, self-priming floor coatings are highly dependent on the condition of the substrate. For it to work, it requires a well-finished and good-quality substrate. Plus, its “priming” property doesn’t have the ability to prevent osmotic blistering. Therefore, we highly discourage the use of self-priming floor coating, especially for cold or humid areas.

The Right Method and System

The key to preventing blister formation is knowing the right methodology and system.

As always, floor preparation is paramount. However, using the right primer is just as important; and an excellent primer should have a moisture barrier property.

Here at Buildrite, we recommend using a floor primer that provides excellent adhesion to the substrate and prevents the formation of blisters or bubbles.

Buildrite Epocoat MB is a two-component, 100% SOLID EPOXY specially formulated as a high-strength primer and moisture barrier for subsequent topcoat or topping systems. It serves as a primer, sealer, and protective barrier to provide an excellent preparatory surface for the application of subsequent floor coatings.

With its ability to block moisture, Epocoat MB is the go-to primer for all floor coating systems as it provides many other benefits:

- Better mechanical bond to the substrate as it penetrates into the concrete

- Excellent chemical bond when topped with thicker epoxy-based floor coatings

- Promotes coating uniformity as it prevents the floor coating from being absorbed into the concrete pores

- Eliminates the need to measure the moisture content of the substrate

- Works even applied on concrete that has not fully dried from being cleaned

Say Goodbye to Floor Coating Problems

Installing a new floor coating is a big investment, and we expect it to last for many years.

When the floor coating fails, however, it becomes a big headache that needs to be addressed immediately. In some cases, it can even cause delays in the operations of a business, especially in commercial and industrial settings.

Fortunately, with a little bit of research (and the help of an expert), you can lengthen the lifespan of your floor coating by installing the correct system.